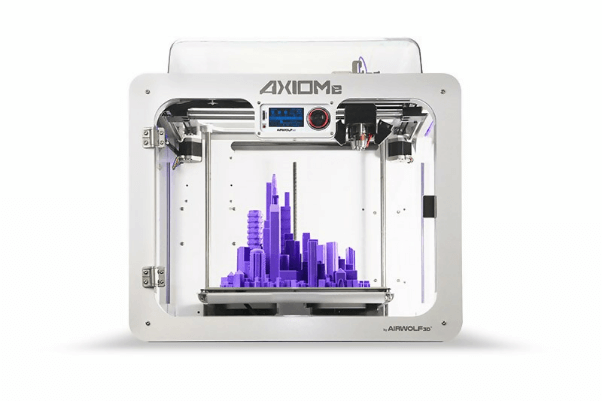

3D printing can be the fastest method of printing and it is a lot more cost-effective when creating prototypes as well as one-off parts. Buying a 3D printer part is usually determined by the amount of material which is used in all the process and the manufacturing period.

One of the main factors that determine just how much 3D printing cost is the materials involved. The material cost which is the cost of a 3D standard printing and can be gotten at $25 a kilogram when getting FDM filaments. You can get $50-50 a kilogram if getting SLA resins and SLS Powders. Another thing to consider is the part volume. Larger parts usually require more materials and also take longer to print and this increases their cost.

When a print has been completed, post-processing follows and there might be the need for added manual work to finish a part urgently which can result in more cost. A set up is usually small when 3D printing is involved and that is for a logical reason why printing is more economical in lower numbers and why it becomes less pricy to other machines such as CNC or injection molding of higher volumes.

If a price is a design restriction for a person, then they can opt for FDM which are great printing options. This is because FDM filaments are usually cheaper than SLS powders and SLS resins. Another reason is that the FDM parts are usually partly hollow when printed, therefore making use of lesser materials and you should know other printing processes develop parts that are a lot more solid.

There are a lot of ways to save this printing cost if you choose other models or even an FDM model and some of them include:

- Scaling down your 3D model greatly in order to reduce the cost of printing.

- Hollowing your 3D model is another great way to reduce cost so if your fully solid object doesn’t seem necessary, then go ahead and follow it.

- Eliminating the need for support structure is another good way to save the cost of 3D printing. These supports are usually used in FDM for creating parts with overhangs but they can increase the cost of printing. There are two different ways to eliminate this such as splitting your 3D model or overhang angles.

You should know that FDM is probably the most economic 3D printing process there is. You can reduce the volume of the part by scaling down or even hollowing the model in order to reduce the cost of SLS and SLA printing, significantly.

Also, you can reduce cost by designing parts which do not need support structures in order to reduce more cost when it comes to FDM 3D printing.

Conclusion

These are a few ways you can reduce the cost of printing on your 3D model. So why not give one or all of them a try and see just how much it costs you?