An interesting phenomenon globally is polyurethane casting. There are many reasons to cast polyurethane. The casting method and procedure depend on what you are casting for. Polyurethane is a material with diverse properties that make it useful for many purposes. Some people use polyurethane to make 3D molds for mini-projects or personal use. Other people may use polyurethane for more complex purposes like in machines. Polyurethane has properties that make it soft and useful for things like mold. The same polyurethane has a high load capacity that makes it able to bear the load. Builders can use polyurethane as a platform to keep a high level of loads. Polyurethane has a great capacity either in tension or compression. Whether you are using polyurethane as a soft material or a hard one, you need to cast the polyurethane.

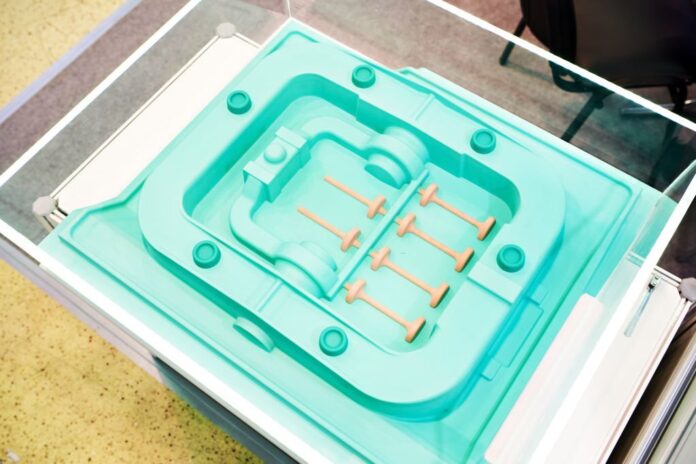

To cast polyurethane for a complex purpose, be sure to go through complicated procedures. If you need polyurethane casting for mold-like purposes, you will need a polyurethane foam. Polyurethane foam has two parts when you buy it newly. The two parts of the polyurethane will remind you of a casting resin or an RTV silicone. Casting a polyurethane foam has more complex procedures than both the silicone and the resin. You’ll need to be more careful because polyurethane because it has a short pot life. Therefore, any mistakes and you won’t like it. This guide will discuss the step-by-step process of casting polyurethane foam. Here, we’ll explain everything you need, from materials to the casting process. Let’s go!

Gather all tools and materials

Casting polyurethane foam independently can not be done without the necessary tools and materials. Of course, the most important material you will need in this process is the polyurethane material itself. However, it is not the only material needed. To properly cast a polyurethane foam, you will also need the following materials;

- A small container: it can be a small cup made out of paper or plastic.

- A scale for keeping the material. You can use one plastic bag for the whole process.

- A drill. Choose a drill that has a stirring attachment.

- You may need spoons for stirring purposes.

- A towel. It could be one made out of paper.

- You may need a paintbrush to paint.

- You will need pen and paper to document the different weights of your polyurethane.

Prepare for swift action

When you mix polyurethane, you have approximately thirty seconds before the pot lifespan expires. When this happens, you may need to start again. Therefore, proper preparation is necessary. This is not the time to have all the tools and leave them in a sack. You need to have all of the materials ready in their respective locations. The location of each material shouldn’t be away from your reach.

Mixing the materials

Mixing the polyurethane material is more about getting the proper mix ratio and using the correct container. With the containers already gathered in step one, you should have your sizes. Your mix ratio should depend on how dense you need your polyurethane foam to be. Basically, you will be mixing the polyurethane with water. But you must consciously mix with a spoon. After mixing for a few minutes, you need to demold the mix. All you need to do is wait for about thirty minutes before you demold.