Low-budget 3D printers that are designed for amateur users became hugely popular in 2015. 3D printing techniques and technologies have evolved from being only reserved for engineering project teams to being widely available to any interested persons. The maker community still regards 3D printers as an extremely valuable commodity to have. Selecting the best budget 3D printer recommended for your personal use is not a matter to be taken lightly. Each version has its own advantages and cons. It is best to conduct sufficient research before making a 3D printer purchase as a hobbyist or enthusiast or seasoned professional. Let’s focus on what you should know before buying a budget 3D printer.

Considerations when you purchase a 3D printer

- Type of material used

There are plenty of base materials utilized in 3D printing. You can use any of them to create your next masterpiece. Materials include paper (few machines use paper, but it is still a viable option), ceramic (remember to fire/glaze ceramic parts after printing), gold and silver, plywood/WPC, PLA (a biodegradable plastic), and nylon/polyamide.

- STL file designs

Any proper 3D printer largely depends on STL files to operate correctly. STL files are used as input and are now considered an industry standard. STL refers to Surface Tessellation Language. In this technique, triangles are used to model 3D components.

- Price

This is one of the most important qualities of 3D printers that you need to take into account. Since 3D printing is becoming increasingly popular, the price of the devices is also decreasing consistently. The quality of output for a machine is what determines its price range. Handheld printers are the cheapest brands of devices.

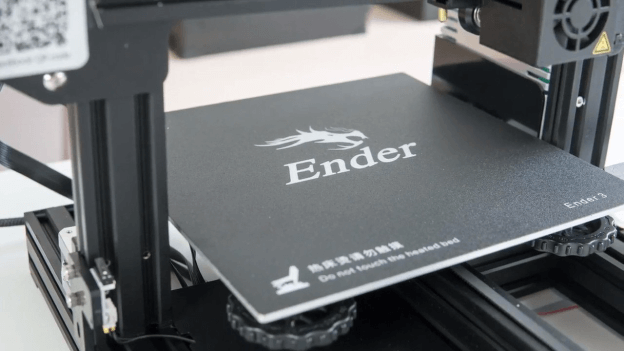

- 3D printer type

The techniques and tools used in 3D printing are constantly evolving. However, a majority of the printers in use today rely on tried and tested techniques including:

- LOM (Limited Object Manufacturing) – plastic components are chopped and melted to allow them to stick together.

- SLS – Selective Laser Sintering uses laser beams to change powder material into solid objects.

- EBM – Electronic Beam Melting works by heating metal in powder form.

- FDM – Fused Deposition Modeling is by far and away from the most popular type of 3D printing. It works by heating plastic components until they melt and then using them to create solid parts.

- SLA – Stereolithography makes use of plastic in liquid form and utilizes STL files to build final object designs.

- Quality

Print speed and its resolution determine the quality of an efficient 3D printer. The horizontal resolution is usually expressed in the XY scale. This gives you the smallest possible movement that the printer is capable of making while crafting a layer. The smallest size of the layer that the printer can craft is referred to as its vertical resolution. The smaller the layers, the smoother the resulting surfaces will be. You should also consider getting a machine with low print speed, as this guarantees good print quality.

Conclusion

With the increasing number of people and niche communities growing around the 3D printing phenomenon, it is proper to consider several things before buying a machine. Know the quality, price, STL file use, and printer type that you require.