Before a product is released into the market, it has to undergo different stages. Nearly every product in the market had a prototype before finished products were made. Rapid Prototyping Services allow for necessary changes to be made to function as required.

Before embracing rapid prototyping, it is vital to understand what the process entails. Every designer or engineer must think about how the product will meet customer requirements. Different designs can be made before prototyping starts. Prototyping allows for testing of different properties, such as aesthetics and functionality. There are times designers want a replica of the final product. These are some advantages of rapid prototyping.

Save Time

As you know, time is quite important in manufacturing. Therefore, in whatever you do, there is a need to save time. With rapid prototyping, you can do away with the time required to make patterns, special tools, and molds that are associated with traditional manufacturing. Since rapid prototyping is highly automated, designers and engineers can quickly change and alter the product. Organizations can gain a competitive advantage by delivering products to your target market quickly.

Save Money

By reducing costs, your customers will be satisfied and happy. Rapid prototyping helps minimize the costs of product manufacturing and development. You do not have to use special tools for new products. Also, automation helps reduce the cost attributed to waste and labor. Modern prototyping methods do not create waste.

Alter the Product Quickly

With a prototype at hand, it is easy to alter the product and implement changes. Remember that there are different steps involved in altering the product before a final one is made. With each step, the product attributes are improved further. As a result, you can build confidence for both developers and designers. Moreover, it helps identify the needs of the customers. As a result, you can make competitive and useful products.

Offers Flexibility

Another good thing about rapid prototyping is that it makes it possible to create and modify custom-made products. It does not require hard-to-use and complex processes. Changes in the CAD model or design cannot affect the entire product development process. You do not have to fear going over your budget as the designers and developers control the process. Hence, no extra costs are associated with the process.

Visualization

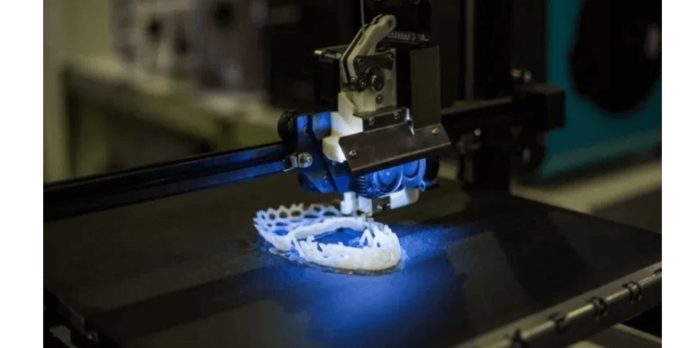

You can make 3D models means that you can help designers present new concepts and ideas to investors. Ideally, investors can understand the entire development process before funding it. Moreover, designers get feedback from clients and customers. They can use the feedback to improve the products. It makes it possible to add realistic and physical data in various product development stages.

Provides Many Opportunities

Rapid prototyping eliminates boring ideas and opens up opportunities for product innovation. That is because it eliminates restrictions that are associated with conventional and traditional prototyping. Designers and innovators can make different models by trying complex surfaces and varying surface textures. You may be surprised to learn that rapid prototyping makes it possible to make shapes and geometries that would otherwise be impossible with traditional prototyping techniques.