Today, surgical masks have evolved from the once-simple strip of cloth that a doctor would tie around his face. Modern masks are created from non-woven fabrics, which are themselves made from polypropylene and other plastics. A majority of these masks are made with the explicit intention of protecting and filtering. You can obtain many different mask designs and finishes; it all depends on the amount of protection required from the mask. With the use of the right surgical mask machines, it is possible to manufacture high-quality surgical masks. Let’s focus on the best surgical mask machines of 2020.

Uses of surgical masks

- To keep the germs and bacteria that are present in the nose and mouth of a wearer from spreading and contaminating a patient’s wound during surgery.

- Surgical masks also work to maintain the sterility of operating rooms.

- It is important to note that surgical masks are not designed to catch minuscule microbes, such as viruses. Compared to germs, viruses are smaller in size and can permeate the pores of a surgical mask.

Manufacture of surgical masks

Non-woven fabric has such qualities as enhanced bacterial filtration. It also possesses heightened air permeability. Despite all this, these fabrics are not as slippery as a cloth that is woven. Polypropylene is the most common ingredient in the manufacture of surgical masks.

Alternative materials that can be utilized in the manufacture of surgical masks include polyester, polycarbonate, polystyrene, and polyethylene.

The best surgical masks in the market are explicitly manufactured with more than one layer. Textile is covered with non-woven fabric on either side of the mask. The more the layers in the mask, the more efficient it is at filtering out bacteria.

One of the most important processes involved in surgical mask manufacture is sterilization, in which the completed masks are sterilized before they can be sent out to clients and warehouses.

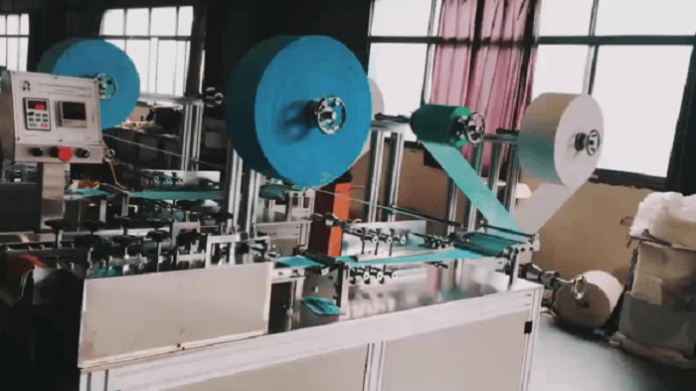

The best surgical mask machines

- Deqi surgical mask making machine

This machine is of enhanced quality, made up of 3 other machine components. These include two ear loop welding machines and one blank mask machine. This machine is fully automated and can integrate material feeding, folding, cutting, nose clip welding, and earloop welding.

The combination of these smaller machines to form a complete surgical mask machine is designed to promote efficiency in the mask manufacturing process.

The advantages of the Deqi Surgical Mask Machine include:

- Easy installation and maintenance

- Presence of high-pressure cranks to automate the process of die opening and closing

- Parts used in the machine are from popular brands.

- Zero pollution and emissions.

- The machine can be automated to run without human interference.

- NCM Nonwoven Converting Machinery

This is a multipurpose machine capable of creating caps, surgical masks, shoe covers, and dust masks.

Advantages:

- The company features some of the best research and design engineers in Taiwan

- Extensive experience designing surgical mask machines over a ten-year period

- The machine design is patented and CE marked

Conclusion

Surgical mask machines are an essential tool in the automated manufacture of surgical and dust masks. It is crucial to buy the right device from a specialist dealer such as deqimachine.com.